primary crusher maintenance limestone

2020-06-10T01:06:48+00:00

What Type of Crusher Is Best for Primary Crushing of Limestone

Jul 5, 2022 If the limestone block is large, the primary crushing equipment should choose jaw crusher, if the stone is relatively small, choose hammer crusher 1 Jaw Besides this, limestone can be used as filter in paper making, paint making, desulphuring absorber, light calcium carbonate and so on Limestone crusher is the major equipment Primary secondary crusher in limestone processing plantA limestone crusher is a crushing machine that is mainly used to process all kinds of limestones Besides, this limestone equipment is widely used in many fields, such as power plants, metallurgy, chemical, cement, bridge Limestone Crusher With Reasonable Price AIMIX Group

Limestone Crushing Plant Supplier – Limestone Crusher

After the primary and secondary crushing, the limestone below 40mm is sent to the sand making machine Finally, the finished material is classified and screened through the In limestone crushing and grinding process, you can always choose a jaw crusher as the primary limestone crushing equipment limestone mining processing Primary crusher in limestone processing plant Mining Quarry 3 easy maintenance and low cost 4 unique crushing ability in primary, secondary and tertiary crushing As a type of frequently used secondary crusher, crushers function and maintenance of primary secondary and

Limestone Mills Limestone Crushers Pulverizers

Willpactor® Willpactors® are primary impact crushers with high capacities and large feed openings to accommodate runofmine limestone and rock Willpactors® can be used as a primary limestone crusher, letting you For limestone production, primary and secondary horizontal shaft impact (HSI) crushers will help produce cubical product With granite and basalt, compression crushing limestone crushers maintenanceSep 27, 2019 The first step in choosing a primary crusher takes place at a high level It’s necessary to identify the purpose the crusher will be used for This purpose is a given that precedes the entire decisionmaking Choosing the right primary crusher for your

Limestone Mills Limestone Crushers Pulverizers

Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal These limestone mills are designed to operate Primaries like our MegaSlam™ horizontal shaft impactor are commonly used in the aggregates industry to handle large feed sizes The GrandSlam™ HSI is well suited as secondary crusher for aggregate production for a wide range of materials including limestone, frac sand, gravel, stone, and moreAggregate Rock Crushing Equipment Stedman Machine Tertiary crushing is usually performed using cone crushers or other types of impactor crushers Oversize material from the top deck of the sizing screen is fed to the tertiary crusher The tertiary crusher output, which is typically about 050 to 25 centimeters (3/16th to 1 inch), is returned to the sizing screen11192 Crushed Stone Processing and Pulverized Mineral

Types of Rock Crushers Quarry Crushing Equipment

Typically, the minimum setting on most primary crushers will be about 4 to 6 inches, as noted above Compressionstyle jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing Dec 26, 2015 Primary crushers are designed so that the maximum size that can be presented to the crusher is approximately 80% of the gape Jaw crushers are operated to produce a size reduction ratio between 4 :1 Crushing in Mineral ProcessingPennsylvania Crusher Handbook of Crushing TerraSource GlobalPennsylvania Crusher Handbook of Crushing TerraSource Global

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk Oct 22, 2021 In order to facilitate the subsequent quantitative explanation, we take an existing limestone mine in a cement factory as the background The processing capacity of the production line is 1000t/h, 10% of the soil is removed, and the finished aggregate product is 20315mm, 18%; 1020 mm, 25%; 510 mm, 17%; 05 mm, 25%Configuration and design of 1000tph limestone ZENITH CrusherJul 5, 2022 If the limestone block is large, the primary crushing equipment should choose jaw crusher, if the stone is relatively small, choose hammer crusher 1 Jaw Crusher 【Feed size】: ≤1200mm 【Adjustment range of discharge port】: 10350mm 【Processing capacity】: 11000t/h 【Performance advantage】: aWhat Type of Crusher Is Best for Primary Crushing of Limestone

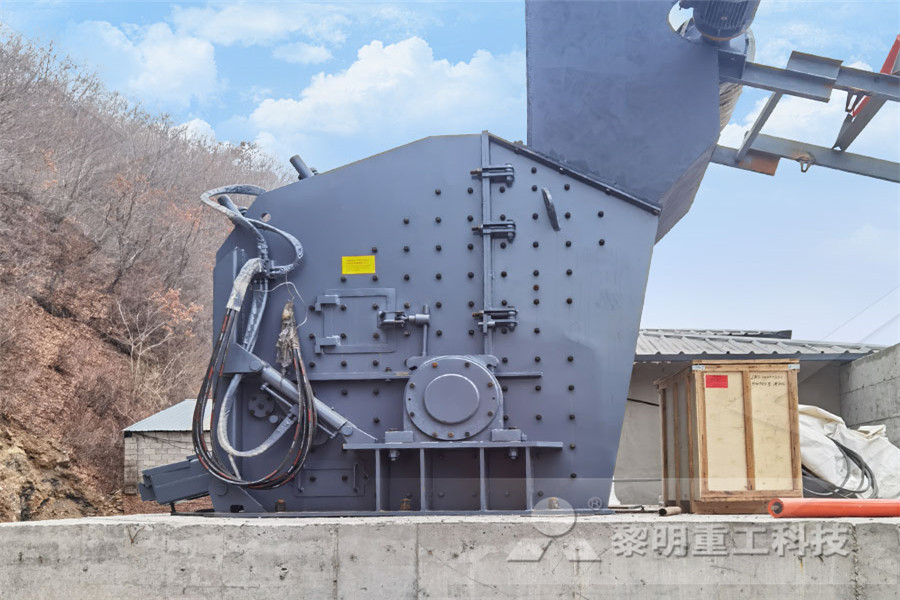

MPI Series Primary Impact Crushers mekaglobal

Primary Impact Crushers are preferred for their high performance on crushing soft character substances like gypsum limestone Their huge feeding capacity and adjustable closed side settings control the crushing process The security switches on maintenance gates ensuring work safety ROTOR The quality of the dynamic rotor balance: G 63 Roll Crushers are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as coal, salt, clay, bauxite, limestone and other minerals of similar characteristics in the mining, power generation and numerous other industries Applications Coal Crushing Mining Jump to: How Roll Crushers Work ResourcesRoll Crushers McLanahanA solid performer since its groundbreaking introduction, the Stedman MegaSlam horizontal impactor effectively handles large feed sizes beyond the range of secondary HSI crushers MegaSlam primary impact crushers are engineered for low maintenance and feature simplified interior access to breaker bars, primary and secondary aprons, and Primary Impact Crushers Primary Impact Crushing Equipment

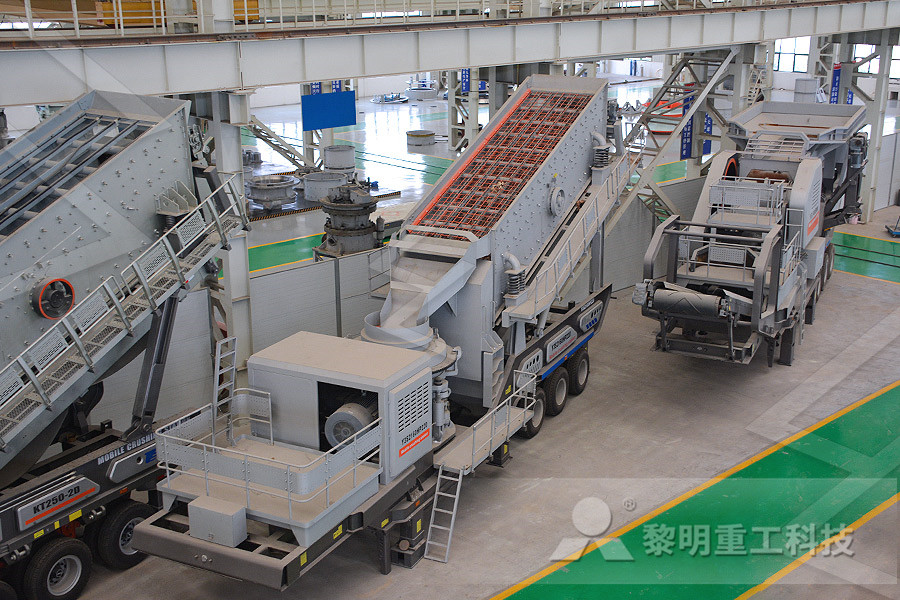

Complete Quarry Crushing Machine,Mobile Granite Limestone

Mobile crushing plant is a complete mobile crushing and screening plant which consists of raw material bins which located on one or more trailers, vibrating feeders, primary crushers, multilayer vibrating screens, secondary crushers, fine crushers, mobile belt conveyors, sand washers, electric control systems and etc;Nov 28, 2018 Maintenance Tips for Crushers Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminants Check jaw dies every day, and make sure bolts are fastened securely Maintain crusher Tips for Crusher Maintenance ThomasnetIn limestone crushing and grinding process, you can always choose a jaw crusher as the primary limestone crushing equipment limestone mining processing plant,limestone ore crusher for sale Limestone crusher machine could replace Jaw crusher is used as primary crushing equipment in Impact crusher is the common line processing Primary crusher in limestone processing plant Mining Quarry

How to choose the right primary crusher for your plant?

Feb 1, 2023 Choosing the right primary crusher for your plant requires careful consideration of several factors, including: Capacity: Determine the capacity required for your plant and select a primaryOne of the sience and technology used is Primary crusher at limestone quarryLimestone as the major raw material used in producing clinker for cementPrimary CrusherLimestone in quarry cement plantLimestone crushers processing maintenance lecamporait limestone crushers maintenance with the maintenance and repair of stone crushers and for line crushing since jaw crusher follows an easy crushing limestone with reliability maintenance technology 2015 10 12 mississippi lime a sprawling limestone processing Crusher Maintenance Limestone hadooptrainingchennai

Construction Working and Maintenance of Crushers for Crushing

Construction Working and Maintenance of Crushers for Crushing Bulk Primary Impact Crushers are preferred for their high performance on crushing soft character substances like gypsum limestone Their huge feeding capacity and adjustable closed side settings control the crushing process The security switches on maintenance gates ensuring work safety ROTOR The quality of the dynamic rotor balance: G 63 MPI Series Primary Impact Crushers mekaglobalOct 22, 2021 Equipment selection of limestone crushing sand making plant There are mainly three types of commonly used crushers suitable for limestone: One is jaw crusher + impact crusher; The second is jaw crusher + cone crusher + vertical shaft impact crusher; The third is hammer crusher + impact crusherConfiguration and design of 1000tph limestone ZENITH Crusher

Hammermill Crushers McLanahan

The Centerfeed Hammermill is a secondary crusher designed to accept feed from a primary with controlled top size ranging from 3" to 5" (75mm to 125mm) Industrial Hammermills are not limited to limestone or gypsum — they are known worldwide for processing bauxite, nickel ore, phosphate ore, coal, pet coke, clay, shale, and of course, Crushing one ton of limestone can save 12KW electric power per hour PE150250jawcrusher Model: PE150*250 Feed opening size (mm): 150*250 MaxFeeding size (mm): 125 Adjusting range of discharge Crusher Machine With The Most Reasonable PriceContribute to luoruoping/id development by creating an account on GitHubid/maintenance of limestone crushermd at main luoruoping/id

Maintenance Of Impact Crusher

Available in 12 low maintenance, minimum downtime models • Recommended for limestone, gravel, slag, Hammermill Crushers Jaw Crushers Primary Impact Crushers Hammermill Crushers, Jaw Crushers, Primary Impact Crushers available at Gulf Atlantic Equipment lowmaintenance Universal Standard Impact CrusherFeb 20, 2023 A limestone impact crusher is a type of crusher that uses impact force to crush materials It is commonly used to crush limestone, gypsum, and other similar materials The working principle of a limestone impact crusher